6 Benefits of a Variable Frequency Drive (VFD)

Variable frequency drives (VFDs) are becoming commonplace in many different industries — and for good reason. These drives control AC motor speed by varying the frequency and voltage supplied to motors and are commonly used for controlling fans, pumps, compressors, and more.

Once you understand what a VFD is and how it works, you may be wondering what benefits VFDs can provide your business. Let’s look at some of the key benefits of VFDs.

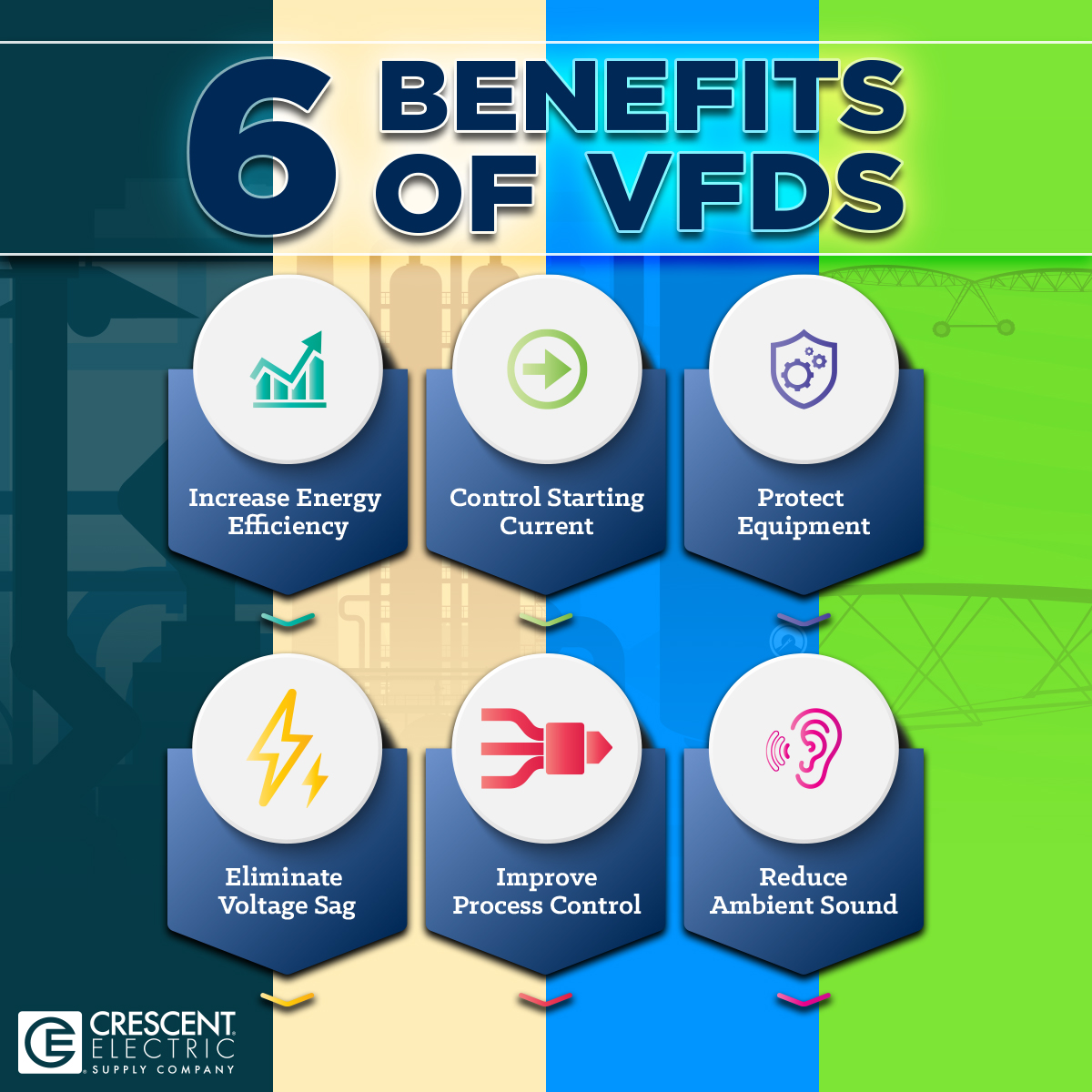

6 Benefits of VFDs

1. Increase Energy Efficiency

One of the primary benefits of VFDs is their ability to improve energy efficiency and, in turn, reduce energy costs.

Motors are often a major source of energy consumption, especially for industrial facilities. VFDs help reduce energy costs by regulating motor speed, specifically in cases when the motor doesn’t need to run at full power or at a consistent speed. And a little can go a long way — because the relationship between motor speed and energy consumption is cubed, energy savings can stack up quickly.

2. Control Starting Current

Another benefit of VFDs is their ability to keep starting current under control, being that they have the capability to start a motor at zero voltage and frequency. This helps limit wear and tear on the motor, which can extend the motor’s lifespan and minimize overall maintenance and repair needs.

3. Protect Equipment

VFDs can also adjust and limit torque, ensuring that the motor doesn’t surpass its torque limit. This helps protect machinery or equipment from damage and mitigate potential process interruptions.

4. Eliminate Voltage Sag

Voltage sags are short-term reductions in voltage. In industrial settings, voltage sags can often be caused by starting a large AC motor line. This can be damaging to sensitive equipment such as computers or sensors. VFDs eliminate voltage sag by starting the motor at zero voltage and ramping it up from there.

5. Improve Process Control

For industrial manufacturers, VFDs can be especially useful for adjusting speeds to optimize the production process and maintain quality and consistency. VFDs can be programmed to run motors at the optimal speed or stop at specific positions, providing tighter process control compared to other motor control methods. Many VFDs can also be controlled remotely.

6. Reduce Ambient Sound

While it may not be the primary reason for a VFD, operating motors at lower speeds can reduce ambient sound levels. Reducing ambient sound, especially in industrial settings, can improve working conditions and communication on the floor.

Experience the Benefits of VFDs Today

Many industries take advantage of the numerous benefits of VFDs — from industrial manufacturing to agriculture. If you’re looking for ways to save on energy costs, improve your processes, and more, it may be time to evaluate if VFDs are the right solution for you.

Crescent Electric offers a wide range of VFDs from trusted brands including Schneider Electric, Eaton, Emerson, and more. Shop VFDs online now or visit our sustainability and energy management page for more tips on how to reduce energy costs!