Industrial Automation: A Complete Guide

Industrial automation is transforming the way businesses operate and revolutionizing manufacturing, production, and industrial processes. By leveraging advanced technologies such as robotics, artificial intelligence (AI), and real-time data analytics, industrial automation enhances efficiency, reduces costs, and improves safety across various industries. These technologies have been so impactful on industrial processes that they ushered in the Fourth Industrial Revolution—commonly referred to as Industry 4.0.

In this guide, we’ll explore what industrial automation is, its key components, benefits, challenges, and the latest trends shaping the future of automated industries.

Why You Can Trust Crescent Electric

If you’re looking to enhance your operations through industrial automation, we can help. Backed by over 100 years of service, we partner with leading suppliers to offer a comprehensive range of industrial supplies and technologies. That said, our commitment to helping you implement industrial automation solutions goes beyond the products we carry. Our team of Application Engineers can help you find the right automation solutions for your business and implement them smoothly. Our team is experienced, knowledgeable, and excited to work with you!

Want to learn more? Reach out to our Application Engineers today and get on the path to transforming your business!

What is Industrial Automation?

Industrial automation refers to the use of control systems, robotics, and advanced technologies to operate industrial processes with minimal human intervention. It enables factories, production facilities, and industrial plants to enhance efficiency, precision, and scalability by automating repetitive tasks and optimizing workflows.

At its core, industrial automation replaces or augments human labor with machines, software, and intelligent systems to streamline operations. This can include everything from robotic arms assembling products on a production line to sophisticated control systems that monitor and adjust environmental conditions in real time.

What are Industrial Control Systems?

Industrial Control Systems (ICS) are the backbone of industrial automation, ensuring machines and processes operate efficiently, safely, and with precision. These systems regulate and coordinate automated equipment by processing real-time data, executing commands, and maintaining stability in industrial operations.

As industries move toward Industry 4.0, modern ICS are becoming smarter, more connected, and integrated with artificial intelligence and machine learning to enable autonomous decision-making and predictive maintenance.

Types of Industrial Control Systems

Different types of control systems are used depending on the level of automation, complexity, and industry requirements.

Programmable Logic Controllers (PLCs)

Known for their adaptability and reliability, PLCs are specialized industrial computers designed to automate machinery and processes by executing programmed logic sequences. They typically consist of a CPU, input/output (I/O) modules, and communication interfaces, allowing them to interact with sensors, actuators, and other control systems. Common applications include conveyor systems, robotic assembly lines, and process control in chemical plants.

Distributed Control Systems (DCS)

DCS is a network of interconnected controllers that manage complex industrial processes in large facilities. Unlike PLCs, which control discrete processes, DCS is used for continuous operations. DCS enables large-scale industrial operations to be automated and optimized, ensuring consistent performance and centralized monitoring of multiple processes. Because of this, DCS is commonly used in sectors like oil refining, petrochemicals, and power generation.

Supervisory Control and Data Acquisition (SCADA)

SCADA systems provide real-time data acquisition and remote control for industrial automation, enabling operators to monitor and control processes from a centralized interface. Their real-time data transfer capabilities make them widely utilized in applications such as utility grids or water treatment facilities.

Other Key Components of Industrial Automation and Control

Outside of ICS, there are several critical technologies behind industrial automation. Let’s look at a few high-level components.

Human-Machine Interfaces (HMI)

HMI systems serve as the interface between operators and industrial control systems, providing visual representations of processes, status updates, and interactive controls. HMIs improve usability and efficiency by allowing operators to monitor and adjust industrial processes in real time, enhancing overall system management.

Sensors and Actuators

Sensors and actuators are essential components in industrial automation, enabling machines to detect environmental changes and respond with precise actions.

Sensors collect real-time data, such as temperature, pressure, motion, or liquid levels, converting physical parameters into electrical signals for control systems. Common types include proximity sensors for object detection, temperature sensors for process control, and pressure sensors for fluid regulation.

Actuators take control system commands and convert them into physical motion or force. They can be electric, pneumatic, hydraulic, or solenoid-based, depending on the required function. For example, electric actuators drive robotic arms, while hydraulic actuators provide powerful motion in heavy machinery.

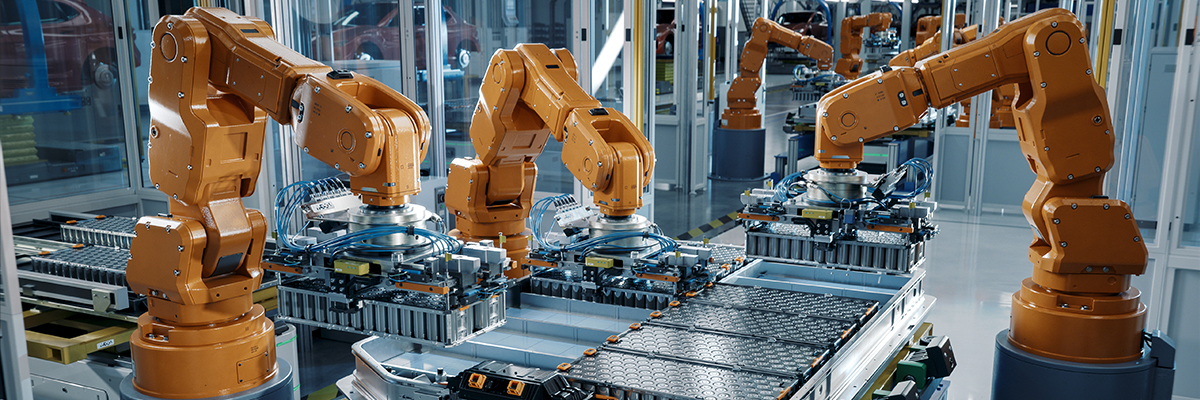

Industrial Robotics

Industrial robots are programmable machines designed to perform repetitive tasks with precision, speed, and efficiency. They enhance automation by reducing human intervention, improving productivity, and ensuring consistency in manufacturing and processing operations.

Key types include articulated robots for complex movements, SCARA robots for high-speed assembly, delta robots for fast picking and sorting, and collaborative robots (cobots) that safely work alongside humans. Robotics applications span industries such as automotive, electronics, logistics, and pharmaceuticals.

Communication Networks

Communication networks enable seamless data exchange between industrial automation components. These networks ensure real-time control, coordination, and optimization of automated processes.

Key types of industrial communication networks include fieldbus systems (PROFIBUS, Modbus, etc.) for device-level communication, industrial Ethernet (Ethernet/IP, PROFINET, etc.) for high-speed data transfer, and wireless protocols (Wi-Fi, 5G, IIoT, etc.) for remote monitoring and flexibility.

Types of Industrial Automation

Industrial automation comes in various forms, each suited to different production needs and levels of complexity—from simple mechanized systems to fully integrated smart factories.

Fixed Automation

Fixed automation involves highly specialized systems designed for repetitive, high-volume production. Once programmed, these systems perform predefined tasks with minimal flexibility. Examples include automotive assembly lines or bottling and packaging machines.

Though they are highly efficient, fixed automation can be costly to implement and modify, making it unsuitable for industries requiring frequent product changes.

Programmable Automation

Programmable automation allows machines to be reconfigured for different tasks by modifying their control programs. This type of automation is ideal for batch production. Computer Numerical Control (CNC) machines, such as a CNC mill or CNC router, are examples of programmable automation.

While more adaptable than fixed automation, reprogramming these systems requires time and technical expertise, limiting their use in fast-changing industries.

Flexible Automation

Flexible automation is an advanced form of programmable automation that allows real-time adjustments with minimal downtime. This is a great option for industries that require quick responses to market changes or customization.

Flexible automation requires sophisticated software, sensor networks, and skilled personnel to manage real-time adjustments, meaning its high adaptability comes with the trade-offs of higher complexity, cost, and needed technical expertise.

Integrated Automation

The cutting edge of industrial automation, integrated automation refers to fully automated systems where machines, control software, and data analytics work together in a seamless, interconnected environment. Machines are connected to a central computer that allows for total production control from a single location.

Integrated automation requires a significant investment in infrastructure, cybersecurity, and workforce training. However, it can offer the highest level of efficiency, data-driven decision-making, and scalability.

Benefits of Industrial Automation

Industrial automation offers numerous advantages, transforming the way businesses manufacture products, manage processes, and optimize operations. Let’s look at some of the key benefits industrial automation can offer to businesses.

Increased efficiency and productivity

Automation enables machines and control systems to operate continuously without breaks, increasing production output and efficiency. Advanced robotics and smart manufacturing solutions can also speed up processes while maintaining high precision.

Improved workplace safety

By automating hazardous or physically demanding tasks, industrial automation reduces the risk of workplace injuries. Robots can handle dangerous materials, operate in extreme temperatures, and work in confined spaces, keeping human workers out of harm’s way. Safety automation technologies, such as emergency shutdown systems and predictive maintenance, further enhance workplace security.

Lower operational costs and waste reduction

Although industrial automation requires a sizeable initial investment, it leads to significant cost savings in the long run. Automated systems can reduce labor costs, minimize material waste, and optimize energy consumption. Additionally, industrial automation technologies may assist with preventative maintenance, which helps prevent costly breakdowns by detecting issues before they lead to system failures.

Enhanced quality control and precision

Industrial automation eliminates the variability associated with human error, leading to higher product quality and uniformity. Machines follow programmed instructions with extreme accuracy, ensuring every product meets the same standards. Quality control technologies, such as vision inspection systems, help detect defects in real time, further improving reliability.

Better data collection and decision-making

Automated industrial systems generate vast amounts of real-time data, which can be analyzed to optimize performance. IIoT and AI-powered analytics provide insights into equipment health, production trends, and energy usage, allowing businesses to make informed decisions. Predictive analytics help prevent failures and improve supply chain efficiency.

Industrial Automation Challenges and Considerations

While industrial automation offers significant benefits, its implementation comes with challenges. In fact, a 2019 McKinsey survey showed that 68% of companies named Industry 4.0 a top priority, but only 29% were deploying it at scale.

Let’s look at some of the primary challenges that businesses face with implementing industrial automation.

High initial investment and integration costs

Implementing industrial automation requires a substantial upfront investment in equipment, software, and infrastructure. From purchasing new hardware to upgrading legacy systems, costs can add up quickly, even for businesses that aren’t looking to fully integrate automation across their footprint. Additionally, companies must factor in ongoing maintenance costs and employee training to operate and maintain automated systems efficiently.

Workforce adaptation and skill gaps

As the industrial workplace becomes more digitized, workers must adapt to heightened technical expertise requirements and modified roles. Not only is this a challenge for businesses, but it also represents an additional cost factor, as investing in training and development is critical.

Cybersecurity risks in connected systems

As industrial automation has become more connected through IIoT and cloud-based solutions, cybersecurity is now a top priority for all industrial businesses—and the numbers show why. According to IBM’s 2024 X-Force Threat Intelligence Report, industrial manufacturing was the most-attacked industry by cybercriminals for the third consecutive year.

To mitigate these risks, companies must implement strong cybersecurity measures, including firewalls, encryption, regular system updates, and employee cybersecurity training.

Compatibility with Legacy Systems

Many industrial facilities operate with outdated equipment that may not be compatible with modern automation solutions. This can mean costly operational disruptions while systems are upgraded, in addition to the costs associated with these upgrades.

Future Trends in Industrial Automation

It’s an exciting time for industrial businesses, as industrial automation and Industry 4.0 have unlocked potentially significant gains in efficiency, reliability, and sustainability. With the speed at which this technology is advancing, it’s important for businesses to keep following the latest industrial automation trends to ensure they keep a competitive edge.

Current trends shaping the future of automation include:

AI and machine learning: While some businesses are already utilizing AI and machine learning, these technologies continue to improve seemingly by the day. There is no shortage benefits AI and machine learning can provide—from optimizing design to enhancing predictive maintenance to improving QC.

Digital twins: Digital twins create virtual models of physical systems, allowing manufacturers to monitor operations, run simulations, and optimize processes in real time.

Industry 5.0: While Industry 4.0 is still a new concept for some businesses, others have already pushed ahead to the next stage. While far more conceptual than its predecessor, Industry 5.0 aims to find the balancing point between Industry 4.0 technologies and human creativity and skill. One of the best functional examples of this is cobots.

Sustainability: It’s not a new trend, but sustainability continues to be high on the list of considerations for industrial businesses. In many cases, automation technologies are helping businesses operate more sustainably by improving energy efficiency and reducing waste.

Final Thoughts

Industrial automation is transforming industries by improving efficiency, reducing costs, and enhancing precision. From control systems like PLCs and SCADA to advanced robotics, sensors, and communication networks, automation enables businesses to optimize processes and remain competitive in an increasingly digital world.

As emerging technologies such as AI, IIoT, and robotics continue to evolve, industrial automation will become smarter, more adaptable, and more sustainable. Companies that embrace these innovations will gain a competitive edge, achieving greater productivity, operational resilience, and environmental responsibility.

Have unanswered questions about industrial automation? Contact our team of Application Engineers today to learn more!